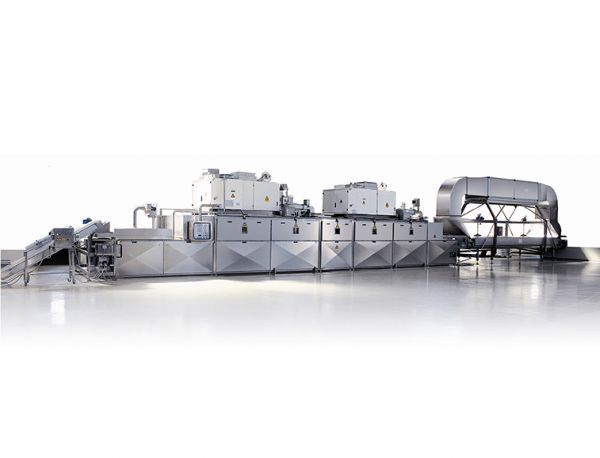

Pasteurisers for packaged products “SANIPACK+”

Traditional pasteurisation methods use hot air circulation, dripping hot water or direct steam injection into the treatment cabinet or tunnel for heating the packaged food. The temperature rise of the product is slow and non-uniform due to poor thermal conductivity of the packaging material, of the air or modified atmosphere contained in the package and within the food substrate itself. In order to reach a given temperature level in the coldest spot of the product a proportionally long heating time is required, affecting in particular the outside layers of food that are more exposed to heat. Consequently, the product loses its quality in terms of sensorial (colour, flavour, texture, etc.) and nutritional characteristics.

The drawbacks of conventional pasteurisation methods can be avoided thanks to the ability of radio frequency to rapidly generate heat volumetrically within the product. The heating process is fast, uniform and controlled, therefore product deterioration is minimised. Stalam is the first company worldwide to have developed industrial pasteurising equipment by radio frequency for packaged products such as fresh pasta, gnocchi, jerked meat, etc.

Benefits

Rapid and uniform treatment

High reduction of the microbial load is achieved in a very short time, thanks to the fast and uniform heating process throughout the product and its packaging, which does not rely on (slow) heat transmission which is typical of conventional methods: the required microbial kill level is achieved in a few minutes rather than one hour or more

No product degradation

The process speed and uniformity minimise the risk of product degradation (especially the deterioration of sensorial, chemical and physical characteristics), thus helping to preserve at best the product quality and freshness, especially in the case of heat-sensitive products

In-line process

Thanks to the high process speed, radio frequency pasteurisation can be carried out continuously, with significant logistic advantages in product handling and production scheduling

Energy saving technology

Considerable energy savings can be achieved, thanks to the fast and selective heating process carried out by the RF field, which transfers the energy directly into the product without losses in the surrounding ambient

Less floor space required

The RF equipment requires less floor space compared to the traditional systems, for the same production output