The Dunlop process: how to improve efficiency and quality in the production of latex foam?

Natural latex is a liquid compound harvested from the rubber tree (Hevea Brasiliensis) whose major cultivations are located in Southeast Asia. Once collected from the tree, the liquid is mixed with ammonia and TMTD/ZnO to better preserve its properties. This standardized LA-latex (low-ammonia latex) is used as raw material to produce balloons, gloves, sanitary articles etc. but also latex foam goods such as mattress cores and pillows.

DUNLOP process: the origins

In 1887, John Boyd Dunlop (1840–1921), born in Scotland, invented the first inflatable tire for his son’s tricycle based on the thermal vulcanization of natural rubber and then patented it on December 7, 1888. Two years later, however, his patent was officially invalidated because another Scottish inventor, Robert William Thomson (1822-1873), had already patented the same technology in Great Britain, France (1846) and in the USA (1847). Nevertheless, the process was named after Dunlop and became the main system for vulcanizing rubber and latex foam products.

Technologies become industrial standards: DUNLOP and TALALAY methods

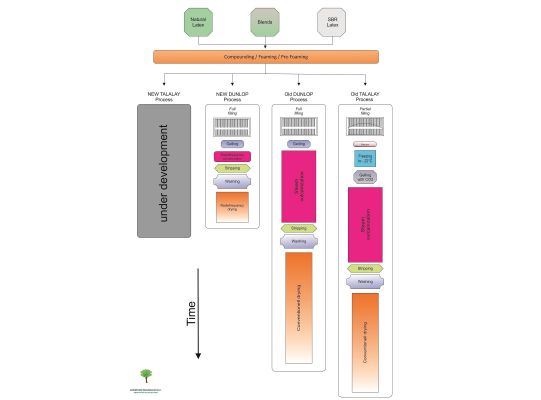

There are currently two standard methods for the production of latex foam items: the DUNLOP and the TALALAY processes. Invented in the late 1940, the TALALAY process takes longer time and is more complex than the DUNLOP process. This system is used just by few producers worldwide and has just a small market share. The basic raw materials in both systems are natural latex (NL) or SBR-latex (styrene-butadiene-rubber) or blends of both.

The DUNLOP method

If pure natural latex is used, the latex “milk” is mixed with the required chemicals. Once matured, the compound is foamed up with a mechanical mixer (SBR-latex can be foamed up without maturing) and filled into metal molds. A gelling agent is added to the mixture, to generate a fast reaction that stabilizes the foam structure. The molds are then placed in a steam oven or tunnel to vulcanize the cores. Since foamed products are good thermal insulators, the molds are fitted with a large number of pins to transfer the heat into the foam itself. Once vulcanized, the pillow or mattress core is stripped, washed, dried and is finally ready for sale.

The TALALAY method

In the TALALAY process three more phases are necessary before the vulcanization step:

– the mold is only filled by 40-60%. Then it is closed and air is pumped out to expand the foam to fill the entire volume of the mold;

– the foam is frozen to -20°C to stabilize the structure;

– CO2 is injected though a valve into the mold to gel the foam.

The rest of the process follows the same steps of the DUNLOP process, i.e. vulcanizing, stripping, washing and drying.

The traditional Dunlop vulcanisation process uses steam as the heating mean to activate the cross-linking reactions of polymer chains. Foam, having plenty of tiny air bubbles within, is by nature a poor thermal conductor and therefore letting heat soak into thick mattress core or pillow molds is a slow and inefficient process. Costly and heavy metal molds fitted with many metal pins are actually used in the attempt to speed up the process, but it still remains time- and energy-consuming.

During the decades some chemicals have been replaced to improve the overall process, but the basic process, ie. the cross-linking of rubber molecules with sulphur, hasn’t changed up to date, along with the typical drawbacks of conventional heat transfer methods.

Slow process, high energy losses. Is there a solution? Yes, there is!

The “new Dunlop process”

The Radio Frequency technology overcomes the main inconveniences of the traditional Dunlop process because it does not rely on heat transfer, so even thick, shaped and dense latex foam items (mattress cores, anatomic pillows, etc.) can be heated up and vulcanized quickly: actually, Radio Frequency is instantly absorbed in a controlled amount (adjusted as required by the machine itself) by the water contained in the foam, uniformly throughout its volume. Thus, heating of the foam and its full vulcanization just take a few minutes, in the center as on the surface.

The RF vulcanization machines are therefore much smaller (shorter) compared to the conventional carousels or tunnels working with steam having the same hourly throughput, and the energy consumption can be cut as much as 50%.

Molds can be made of light and inexpensive composite materials that allow weight reduction of over 60% compared to traditional metal molds: the reduced mold mass contributes significantly to the lower energy consumption. Moreover, appropriate mold materials allow for an easy and quick stripping of the vulcanized items. Last but not least, mold design is more flexible, not being bound to the presence of pins.

It should also be mentioned that the Radio Frequency technology can be successfully used even for the production of continuous latex foam sheets (LPC , topper or even a true mattress) up to 12 cm thickness and more, in a much shorter time and reducing significantly the energy consumption, considering also that the traditional steam vulcanization of sheets thicker than about 5 cm is an almost impossible task due to the lack of heat penetration in the absence of metal pins.

What about latex foam drying after vulcanization, washing and squeezing?

The same technical reasons that make Radio Frequency more efficient and cost-effective compared to the traditional steam-based vulcanization methods, can be applied to the final drying phase of latex foam products after washing and squeezing.

The benefits of using Radio Frequency dryers rather than steam-heated dryers can be summarized as follows:

- fast and uniform drying: about 20 minutes are sufficient to dry even thick and dense mattress cores below 1% residual moisture content, without any wet spots; also shaped products like pillows and anatomic seats dry perfectly uniformly in thicker parts as in thinner portions;

- no yellowing of the product surface, due to low temperature in the drying tunnel (RF heats the product core, not its external surface);

- short conditioning time, so the product can be packaged for shipment quickly after drying without any risk of moulding on the way to customers;

- significant reduction of drying equipment footprint, thanks to the short process time;

- energy-efficient in-line process, reduced drying and product handling costs;

- reduced carbon foot-print, being an electro-thermal technology.

It can therefore be said that the Radio Frequency technology is a real revolution in the latex foam industry, both in the vulcanization and the drying phases, providing latex foam producers with huge benefits in terms of production efficiency, cost saving and product quality.

(the picture is a courtesy of Latexfoam Technology B.V.)