One of Europe’s largest soft wheat mills partnered with Stalam to enhance the quality of their soft wheat bran and rye flour. The adoption of Stalam’s radiofrequency (RF) technology significantly improved the sensory and microbiological parameters of these products.

The milling industry faces challenges in maintaining the quality and hygiene of flours and by-products. One of the most critical issues is reducing moisture and microbial load to prevent long-term spoilage and the formation of aflatoxin-producing molds, which are harmful to human health.

The customer aimed to increase the market value of its soft wheat bran and rye flour by lowering moisture content and improving the microbiological profile, making its products more attractive in the healthy food market.

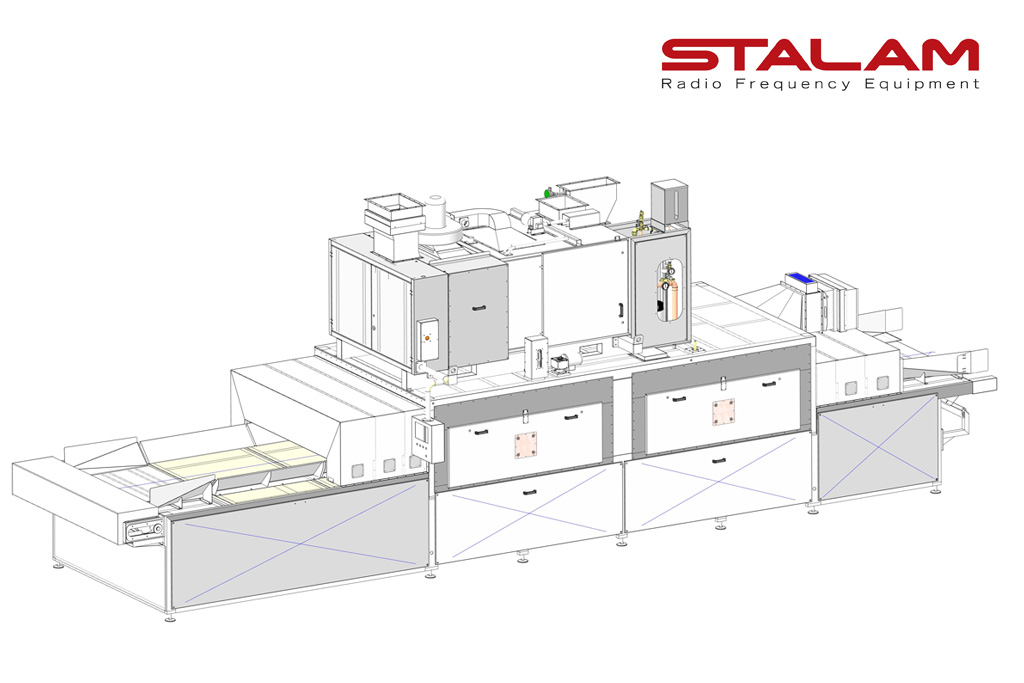

The RF Solution

Stalam’s radiofrequency equipment was designed to perform a combined process: drying, sanitizing, and light roasting. The machine uses a continuous conveyor system equipped with an 85 kW RF generator and controlled air circulation inside the treatment tunnel.

Stalam carried out pilot tests that demonstrated the RF technology’s ability to not only reduce moisture in the bran and flour to the desired levels but also significantly lower microbial load. Additionally, the process enhanced the sensory characteristics (color and flavor) of the product through controlled light roasting.

Benefits and Results

- Efficient Drying: Moisture was reduced to the optimal level for long-term storage.

- Sanitization: A significant reduction in microbial load (molds and total bacteria count) was achieved.

- Sensory Improvement: The light roasting process improved the color and flavor, making the products more appealing to consumers.

Stalam’s 85 kW RF system, capable of processing 750-1000 kg/h of bran or flour, has been operating with full customer satisfaction for over two years. The customer reported that Stalam’s RF technology has enabled them to produce higher-quality products with optimal microbiological and sensory characteristics.

“We are extremely satisfied with the results achieved through Stalam’s radiofrequency technology. Not only has it improved process efficiency, but it has also enhanced the quality of our products, making them more appealing in the market.”

Stalam’s radiofrequency technology offers an innovative solution for processing products in the milling industry, combining drying, sanitization and sensory improvement in a single process. For more information, feel free to contact us.

FOOD

Disinfestation and sanitisationRadio frequency provides a fast, chemical-free solution for agricultural pest control

Discover More

FOOD

SANICROP+Disinfestation and sanitisation of agricultural commodities with radio frequency

Discover More