Mexico strategic location, and strong economic growth has led to an national protein consumption to be raised slowly but steady in the past decades. People are now looking for more sources of protein, Mexico historically has been a big poultry consumer and is part of a traditional Mexican diet to include poultry in the everyday menu. Global situation is very volatile and local production cannot match the internal market demand for poultry products, that´s why Mexican producers have to find different sources of poultry, pork and beef raw material outside the local market; that means to bring frozen products from other places to keep up with the local market demand for protein products.

Stalam and its partner, Epsilon Soluciones, as a partner of technology to all of mexican customer, are always promoting more efficient ways to process protein in the area. After years of marketing, testing, analyzing and negotiation we had the opportunity to work together with two big customer within the Mexican market, both located strategically in the north of Mexico, one in Monterrey, the Industrial Capital of Mexico “JJ ALIMENTOS”, and the other one in La Laguna region which is one of the strongest industrial and protein processing center in Mexico “PILGRIMS México”, part of JBS.

With both big customers we have supplied the STALAM RF Technology in order to improve quality, reduce plant space, reduce time and increase yield in their defrosting operations, in less than a few weeks both customer increase in more than a 100% their defrosting capacity and also worked with a 0% yield loss in their defrosting processes. Using the Stalam RF technology it has proven also to be more energy efficient than expected compared with the technologies they used prior to the acquisition of the Stalam equipment that means also a big financial benefit just for running the machine instead of doing in their previous processes.

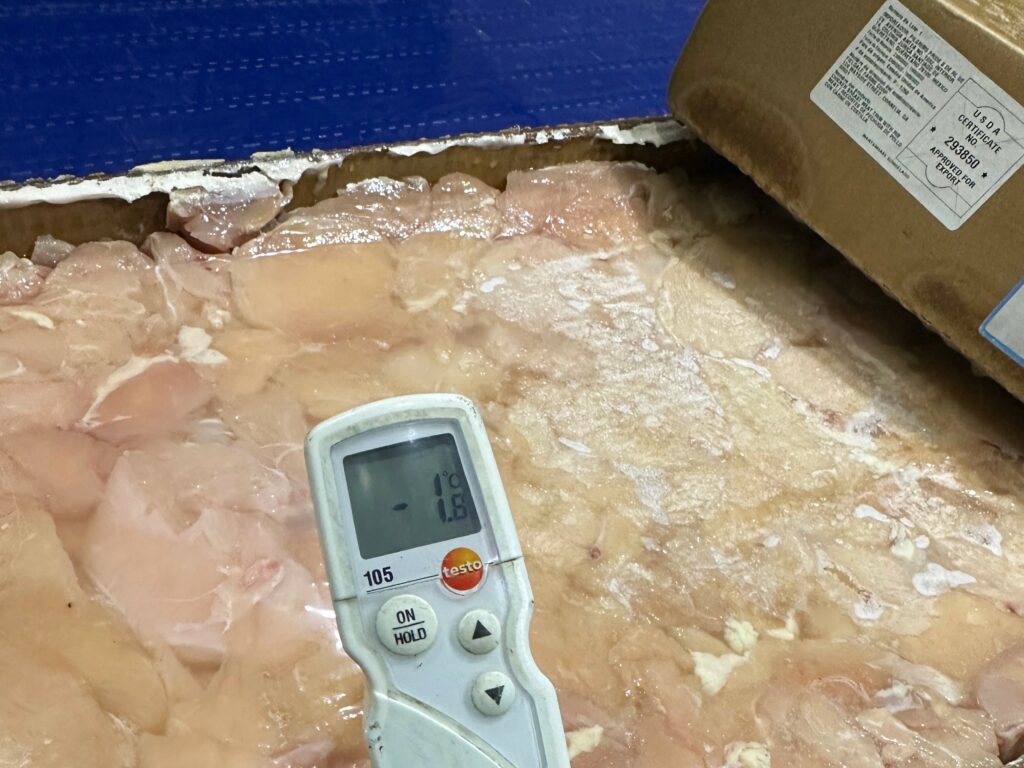

“JJ ALIMENTOS” owns a COLDWAVE+ 85kW that is used for tempering about 1500 – 2000 kg/h of frozen blocks of chicken (with and without bones) from -18°C to around -2°C. The thawing is then completed in defrosting tumblers. Thanks to the STALAM machines the total thawing time has been reduced of 60%, thus increasing the production capacity of around 2.5 times, improving the quality of the product and yield.

“PILGRIMS México” owns 2 machines COLDWAVE+85kW used for tempering around 3000 – 4000 kg/h of frozen blocks of chicken and pork bellies. The processing time is around 25 minutes. Even here the processing time has been drastically reduced compared with the previous defrosting system and the yield improved.

STALAM RF Technology has proven to be a very accurate bet for the protein processors because of the reliability of the technology and also because of the big benefits it represents, time, resources, energy, quality and control. Both of our customers had much better results than expected and the simple fact that they can run more than double of their capacities using less time, less space and less energy and having a 0% yield loss, meaning that Stalam technology is one of their best investments in the poultry processing lines in the last years.

The results speak for themselves, when talking about defrosting , now also our customers in Mexico and in America know that STALAM is an essential partner for success and will keep using them for the benefits it accomplishes giving these results not only to our customers, but to all the supply chain involved in the poultry processing.