A breakthrough in the efficiency and sustainability of a production process.

In the fast-paced world of food processing, maintaining high product quality while meeting the market demand for faster delivery is no easy feat. For a leading European food processor, renowned for its expertise in poultry products and poultry-based ready meals, this challenge became a pivotal focus.

The company sought a solution that would not only speed up their production cycles but also ensure that the quality and texture of their products remained consistently high. The solution came in the form of a radio frequency (RF) equipment, specifically the Stalam’s “Coldwave+” defroster.

For years, traditional defrosting methods (tempering rooms, forced-air cabinets, water bath, etc.) have been the standard in the industry. However, these methods are slow, energy-intensive and result in uneven defrosting, which affects the texture and quality of the product other than generating bacterial growth issues.

The company faced mounting pressure to improve efficiency and reduce energy consumption, all while adhering to strict product quality and sustainability goals. With defrosting times of its poultry meat stretching far longer than affordable, the company recognized the need for a change.

Over a decade ago, the company had already explored RF technology during its early stages in defrosting applications. At that time, there was a misconception equating RF with MW technology, which had not yielded successful results in a different facility. This misunderstanding led to a halt in RF-related investments.

In the summer of 2023, they revisited the RF technology, inspired by the impressive number of Stalam RF units successfully operating in the market. With a deeper understanding of RF technology and its distinction from MW, coupled with valuable insights from another German poultry industry customer already utilizing two Stalam RF machines, they confidently decided to invest in RF equipment.

The RF “Coldwave+” defroster, a highly advanced piece of equipment, delivered what was meant for. Its ability to rapidly and evenly defrost all kinds of frozen meat without compromising in quality, made it the choice for the company.

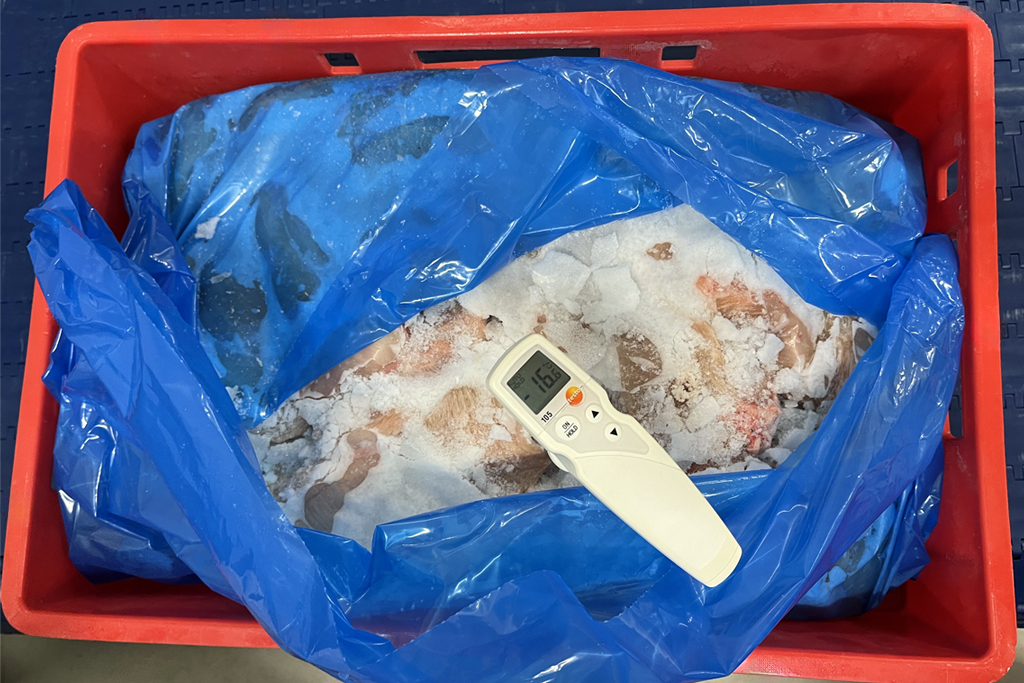

The RF “Coldwave+” defroster works by using radio frequency energy to penetrate food products uniformly. Unlike traditional defrosting methods, which rely on external heat sources and heat transfer through the product surface, the RF energy is absorbed directly by the food throughout its entire mass, thus enabling a uniform and rapid defrosting process.

The modular design of the RF “Coldwave+” defroster allowed the company to integrate it smoothly into their existing production line. Due to the large defrosting capacity required, three RF modules were assembled in-line, yet with a minimal disruption of daily operations in the company. And despite its advanced technology, the equipment proved to be incredibly user-friendly, requiring little training to the operators and delivering quickly and consistently the expected results.

The results were nothing short of transformative. The company saw a drastic reduction in defrosting time, increasing dramatically the production throughput. What’s more, the quality of the defrosted poultry was excellent: texture, flavor and nutritional value were preserved at their best. The uniform distribution and accurate control of the RF energy delivered to the product’s entire mass ensured that the poultry was never overexposed to heat (i.e. over-defrosted on the surface), which had been a common issue with older defrosting methods.

In addition to saving time, the company experienced a reduction in energy consumption, which not only helped cut operational costs but also aligned perfectly with its sustainability targets. The RF “Coldwave+” defroster’s energy-efficient operation has proven to be an invaluable asset, reducing the company’s environmental impact while improving its overall profitability.

As more food processors look to meet the dual demands of efficiency and sustainability, solutions like the RF “Coldwave+” defroster are proving to be key. With its ability to deliver faster production cycles without compromising on quality, the RF technology is helping shape the future of the food processing industry.

FOOD

Drip Loss Calculatorstimate the payback of the investment in a STALAM defrosting machine.

Discover more