A prominent North-European player in the plant-based food sector, whose mission is to promote healthier nutrition habits by introducing to the market innovative meat alternatives, has recently adopted Stalam’s advanced RF (radiofrequency) technology specifically for defrosting the frozen ingredients used in its production facility.

As a part of its mission to offer healthier and more sustainable food options, the company focuses on producing high-quality and tasty meat alternatives that have a great appeal to environmentally conscious consumers.

Stalam’s RF equipment enables the rapid and uniform tempering of raw food materials with minimal drip losses, helping to preserve the texture, flavor and nutritional value of the products. By integrating RF defrosting into its operations, the company has ensured that ingredients like plant proteins, vegetables, fruits and other raw materials are defrosted quickly and consistently, without the quality loss often associated with traditional methods. This technology has become a cornerstone in the company’s business model, allowing it to keep up with growing demand in the plant-based food market with top-notch products.

The RF process not only ensures a higher quality standard but also reduces energy consumption while improving the production efficiency and logistics thanks to its in-line operation. Last but not least, RF defrosting is an environmentally friendly technology, as the energy required for the equipment operation may come 100% from renewable sources: a sustainable technology for more sustainable food.

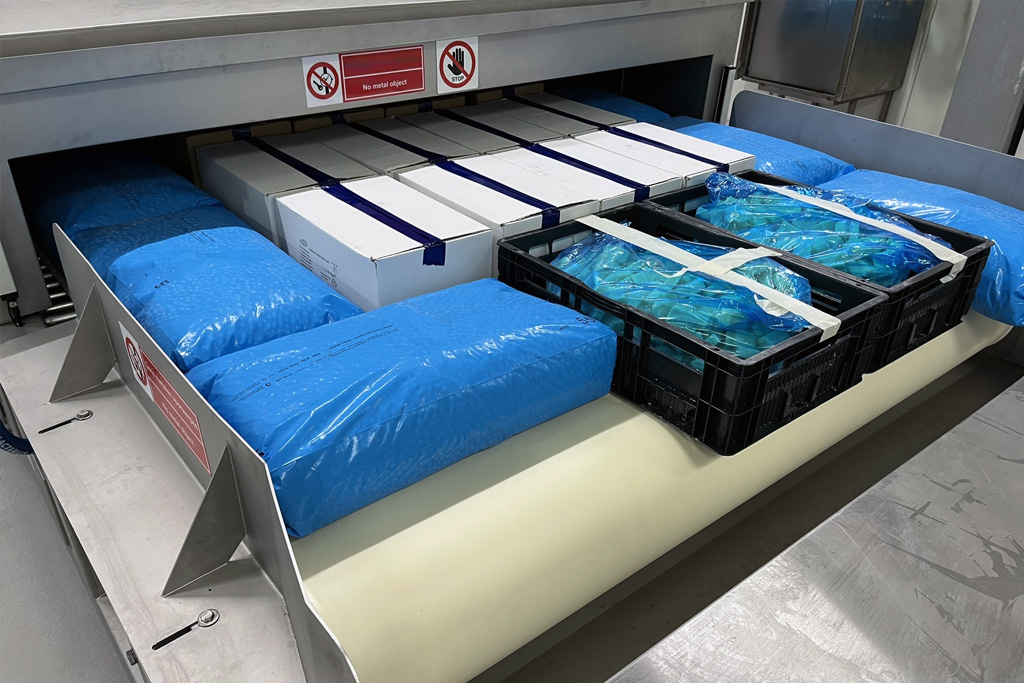

The RF defrosting process can be performed on IQF products or on bulk-frozen blocks. The Stalam COLDWAVE+ 105 kW model chosen by the company is equipped with an adjustable electrode system and with a wide conveyor belt that enable processing a wide range of sizes and weights: from a few kilograms of small-size IQF fruits to 30 kg blocks of bulk-frozen vegetables.

Stalam RF defrosters can be customized based on specific customers’ needs in terms of production capacity (from a few hundred kg/h to several tons/h) and according to the characteristics of the products to be defrosted: packaged (in PE film/liner or bag, open or vacuumed, PE + carton, PP crates or trays, etc.) or in bulk.

FOOD

Rapid defrostingDefrosting is achieved in minutes rather than hours/days, even for large product blocks

Discover More